|

|

|

|

Core Moto SS performance brake lines are made in the USA using the highest quality materials and machinery available. The level of quality materials and processes used to make each Core Moto brake or clutch line is felt directly by the person operating the motorcycle they were installed on.

Core Moto lines are made custom to order and usually ready in 12 hours from time of order!

Why Choose Stainless over Rubber Hoses?

OEM rubber hoses expand and swell, especially under extreme braking conditions. This expansion results in what is often described as a spongy feel or brake fade. Most motorcycle manufacturers recommend that your OEM rubber brake lines be replaced every 4 years when used under normal conditions. Core Moto SS Performance lines are good for the life of the motorcycle.

Core Moto lines do not expand under pressure or fatigue. All braking input is transmitted from the master cylinder directly to the calipers, giving you complete control, feel and feedback from the final point in the braking system. Total brake response and performance is improved with this often overlooked yet simple modification.

All Core Moto brake line kits include stainless steel fittings, stainless steel ferrules, stainless steel Tefllon hose, stainless steel banjo bolts, and copper washers (NOT ALUMINUM) to offer you a complete replacement . Core Moto kits also come with a lifetime warranty.

High performance braking is not just for the race track!

Get more from your brake system with Core Moto SS Performance Brake lines.

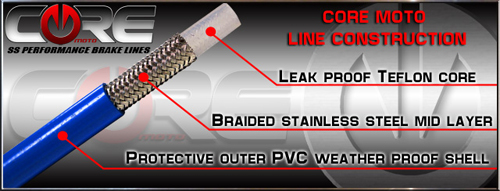

Core Moto stainless steel brake lines are made using only top grade

materials and construction. Each line features an inner core Teflon

hose wrapped tightly in a woven cold drawn high tinsel 32 strand

stainless steel braid coated with a PVC outer shell for superior

strength, corrosion resistance and elimination of brake line expansion

and fade. Available in 19 color options.

Line material from other

companies may look the same but the real quality lies in the chemistry

and composition of the materials being used. Our Teflon core

stainless steel lines can be bent 18,000,000 times before rupture

compared to only 750,000 bends of the standard PTFE used by other

companies. Our Hoses have been batch tested to 18,000 psi without

failure. (normal motorcycle braking pressure is 800 - 1,000 psi) So most

companies only test assemblies up to to 5,000 psi. We choose to use

line material that out performs industry standards.

All Core Moto banjo fittings are High Grade CNC machined and polished stainless steel (NOT ALUMINUM) Even our Colored banjo fittings are

stainless. Also available in Titanium. With nine different colors to

choose from,we have the largest selection of color options on the

market. Finding he right color option for your custom look has never

been easier.

Also, our color banjo fittings are ( NOT COLOR ANODIZED) so color fade from sunlight exposure is not a concern.

In most cases when ordering a front brake line kit for any dual front

disc system, we will construct a 2F routing kit. The 2F kit delivers the

best performance

because fluid pressure is evenly distributed to each caliper

simultaneously for optimum breaking feel and performance. Other routing

options may available upon

demand. Some bike models require other routing systems for proper brake

function and can not be fitted with the 2F set up. In fact some

motorcycle can use

up to 10 lines for a front an rear brake system, however this is not

common. If your application requires more than the most common 2 front 1

rear line set up, the

kit will be priced according to the total amount of individual lines

required. See pricing section for details.

F= As described above this layout uses 2 lines connected to the

masher cylinder and delivers pressure to each caliper simultaneously.

S= Standard or direct factory replacement, usually and S layout will follow the same routing as factory lines.

O=

Over the front fender, this is also typically a factory layout but can

be requested on some motorcycles. This layout makes one caliper the

Primary caliper and

transfers pressure to the secondary caliper.

1,2,3,4,5..... This represents the amount of lines required for each system.

Premium Brakes & Parts at NiceCycle.com

Premium Brakes & Parts at NiceCycle.com

Upgrade your motorcycle's braking system with our top-of-the-line brakes and parts. At NiceCycle.com, we offer a wide selection of high-quality brake components suitable for all types of riders and motorcycles. Whether you're cruising the highways or hitting the racetrack, our brakes and parts provide the reliability and stopping power you need.

🔧Why Choose Our Brakes & Parts?

- Superior Stopping Power: Engineered for optimal friction and durability.

- High-Quality Components: Made from premium materials to ensure extended life and performance.

- Easy Installation: Designed for a perfect fit and hassle-free replacement.

- Wide Compatibility: Suitable for a variety of motorcycle makes and models.

💰Price Match Guarantee

We are committed to offering you the best prices. If you find a lower advertised price from any authorized dealer, we'll match it! Shop with confidence knowing you're getting the best deal possible.

👤Customer Service From Riders

Our team is composed of passionate riders who understand your needs. We provide personalized assistance to help you find the perfect brakes and parts for your motorcycle. Reach out to us for expert advice and recommendations.

🏅Military and First Responder Discount

As a token of our appreciation for your service, we offer exclusive discounts to military personnel and first responders. Contact us to learn more about how you can save on your purchase.

☎Contact Us

★What Our Customers Are Saying

★ ★ ★ ★ ★

John 🇺🇸

"The brakes I purchased have transformed my riding experience! Exceptional stopping power and smooth performance."

★ ★ ★ ★ ★

Emily 🇺🇸

"As a first-time buyer at NiceCycle, I was impressed with the customer service. The team helped me choose the right brake parts for my bike."

★ ★ ★ ★ ☆

Michael 🇺🇸

"Great quality brake components at an affordable price. The military discount was a nice bonus!"

★ ★ ★ ★ ★

Sarah 🇺🇸

"Fast shipping and excellent product quality. My motorcycle's braking has never felt smoother."

Experience the difference with premium brakes and parts from NiceCycle.com. Your safety is our priority, and we're dedicated to providing products that deliver exceptional performance every time you ride.

|

|

|

|

|

|

|